Common trade names include Titanium grades 1-4, Titanium alloy, Pure Titanium, CP titanium grade 2, UNS Number: R50400

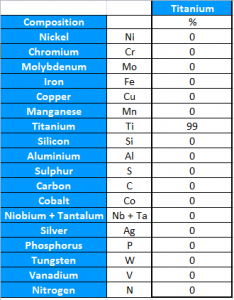

Titanium Properties

Titanium is mainly known for its high strength to low weight ratio and outstanding performance in areas of corrosion resistance.

Titanium was discovered by William Gregor in 1791 and was later named by chemist Martin Heinrich Klaproth, inspired by the Titans in Greek Mythology.

The current extraction and refining method of titanium requires the transfer of soil to factories, where the ore is then removed. Titanium processing, (also known as the Kroll process) has been standard process since the 1930’s.

Developments are currently taking place that may create a more efficient process, which would introduce titanium as a much more ‘readily available’ alloy, possibly replacing the use of 6MO and even Stainless Steel 316.

The 3D printing of titanium is another intriguing growth in the use of the titanium alloy. Examples of 3D-printed products include medical implants and compressor blades.

Over the years, titanium has replaced heavier and less cost-effective materials within the Oil and Gas, Energy and Aerospace industries. With high strength, toughness even at high temperatures and exposure to otherwise corrosive media, titanium has earned its place in the ‘Special Metals’ category.

This non-magnetic alloy also has low heat and electricity conducting properties. Upon exposure to air, this metal forms a passive oxide coating which protects it from further oxidation. Titanium has remarkable corrosion resistance against seawater, even in high-flow velocities.

Waverley Brownall hold modest stock of titanium grade 2 compression tube fittings, pipe fittings and valves. Titanium fittings will cost approximately 5.0 times the price of our stainless steel range.

What is ‘Grade 2’ Titanium?

Unalloyed, pure titanium is available in various grades. Out of the 4 grades in total, titanium grade 2 is stronger than grade 1 and provides excellent corrosion resistance in the majority of applications. Grade 2 is known for its incredible biocompatibility and is used in the medical industry. It is particularly suited to applications where it is in direct contact with bone or tissue.

(Pictured) High-purity titanium with visible crystallites. Attribution: Alexander C. Wimmer

What does the ‘CP’ in ‘CP Titanium’ mean?

‘CP’ stands for Commercially Pure. Commercially pure titanium holds low density but high corrosion resistance with good weldability and impressive mechanical properties.

Titanium Applications

Titanium has a very wide range of suited applications due to the alloys wide range of favourable properties. In many situations, titanium is the most reliable and durable alloy which extends the performance and service of its forms substantially.

- Marine and Chemical Industry

- Aerospace Engineering

- Medical

- Orthopaedic application

- Heat exchangers

Due to the higher price of titanium, many businesses see the purchase of titanium fittings as a long-term investment for quality and efficiency.

Titanium Tube Fittings

Forms available include seamless tube, hose components, low and high pressure compression fittings, ball valves, needle valves and more. Titanium is also used in the electrical energy, defence and petrochemical sectors.

Standard sizes for titanium tube fittings in grade 2 are up to 1” or 25mm tube OD sizes. For excessive quantities of titanium compression fittings.

Titanium Tube

The most popular tube length to order is 3 metres. Titanium tubing can be provided with orders for titanium compression fittings in both the Ringlok and Duoloc ranges. Titanium tube can also be supplied with titanium components such as pipe fittings and valves.

Recommendation

Waverley Brownall recommends ordering titanium tube and fittings together for your installation.

Material compatibility is important for the Health and Safety of any intended application.

We ask that all purchasers to consider the Health and Safety requirements for the intended use. Temperature, pressure and hazardous media should be vital factors in selecting the correct material, fitting and valve. The mixing of other fittings and tube that is not in the material of Grade 2 titanium will worsen the effects of galvanic corrosion.

Our technical team will be able to answer any questions you may have regarding the use of titanium.

Warning: Waverley Brownall tube compression fittings, valves and pipe fittings are not compatible with other manufacturer brands. We advise strongly not to interchange pipeline components due to risks of application failure. Titanium tube fittings are safe to use alongside other fittings and tube in the titanium grade 2 alloy supplied by us, taking note of the two distinct ranges of single and double ferrule.

Titanium Industry Specifications

ASTM B265 GR2, AMS 4902, ASTM F67, MIL-T-9046CP3, ASTM: Grade 2

Helpful links: