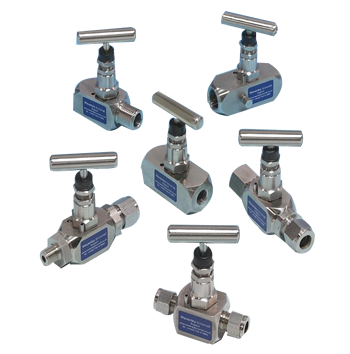

Featuring the World’s most comprehensive range of instrumentation needle valves. The Waverly brownall needle valve range is designed and manufactured to the highest standards to meet the requirements of the severe applications anticipated for these valves. They have a split stem design, which ensures accurate seating, and a bubble tight seal. They are general-purpose valves for use on liquid or gas applications where the isolation of flow, equalisation and venting of pressure are the main criteria. The Waverly brownall needle valve is available ex stock with a variety of end connections from 1/4″ to 3/4″, giving any combination of ends from NPT, BSPP, BSPT, Single and Twin ferrule OD compression. They are available for application up to 10,000 psi and temperatures up to 400 degrees centigrade.

Features

- Non rotating ball tip.

- Provides bubble tight shut off.

- Metal to metal bonnet seal.

- Back seating spindle.

- Prevents spindle blow or accidental removal whilst in operation.

- All threads media free.

- Mirror finish spindle.

- 8 micro inch finish reduces operating torque.

- Self adjusting shaft seal.

- Requires no maintenance.

- Anti-tamper option.

- Prevents unauthorised operation.

- Choice of body material.

- Provides a wide range of valves for many applications.

- Choice of valve packing.

- Providing for higher temperature applications.

Applications

- Instrument line shut off.

- Gauge and instrument isolation.

- Drain/vent valve.

- Up to 10,000 psi or 400°C.

- Liquid or vapour service.

- Downstream pressure release.

- In-situ calibration.

Options

- Sour gas service.

- Valves can be manufactured to NACE.

- (MR-01-75) standard on request.

Oxygen service

- Products can be supplied de-greased for

- Oxygen service on request.

Panel mount

- Valves can also be supplied with a panel mount facility.

Trim

- 316 stainless steel as standard.

- 17.4PH as option

Anti-tamper

- To prevent unauthorised operation of the Valve.

Benefits

- ·T· Bar handle made from 304 or 316 stainless steel. Fastened to the spindle by a dowel type 304 or 316 stainless steel locking screw.

- Colour coded dust capprotects the stem Threads.

- Close tolerance gland pusher allows packing adjustment whilst in service.

- Gland lock-nut ensures the gland nut is positively located.

- Close tolerate gland yoke precision machined from 316 stainless steel.

- Gland packing is PTFE as standard for temperatures up to 200°C.

- Graphite seals are standard for temperatures up to 400°C.

- Spindle produced from 316 stainless steel. Split stem design ensures accurate

- Seating and bubble tight seal.

- Locking pin made from 304 stainless steel ensures that the correct assembly torque of the valve head is maintained against the effects of vibration and/or temperature.

- Bonnet precision machined from stainless steel, housing the gland packing below the actuating threads.

- Bonnet-rotating trim made form 316 Stainless steel, precision machined with Spherical end to ensure a bubble tight seal.

Stainless steel needle valves from £19.50, get your quotation today