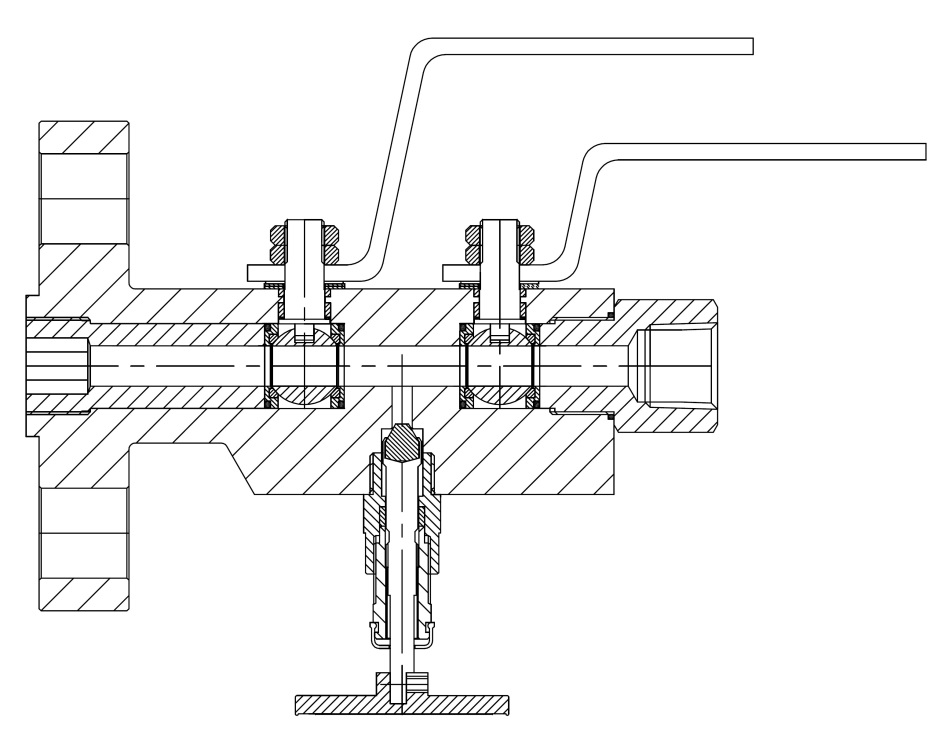

Waverley brownall now manufacture a full range of Double Block & Bleed Valves that provide primary isolation when directly mounted onto process pipework. The WB valves offer an industry standard flanged inlet connection and a screwed vent and outlet connection to suit any instrumentation take off requirement. The valves are available in a multitude of configurations including Single Block, Double Block or Double Block and Bleed. The WB valves all incorporate the well-established WB needle valve head and fully floating Ball Valve Assemblies. The WB valves are available in standard alloys, and many exotic materials to order. The WB valves are designed and manufactured and tested by Waverley brownall in the United Kingdom and can therefore be supplied with a full certification, testing and documentation to meet the specification requested.

Construction

Bar stock or Forged one piece body to give superior grain flow around the flange / body area providing exceptional strength

Configurations

- Single Block Single Block & Bleed

- Double Block Double Block & Bleed

Options available.

Check Valves can be fitted into the inlet or outlet

Inlet units can be manufactured with any flange type as below.

- ANSI B16.5 Flanges from 1/2″ to 4″ in ratings from 150 to 2500 lbs in RF, FF, SRF and RTJ

- API Flanges up to 2.1/16″, 3000, 5000 & 10,000 lbs

Outlet 1/2″ to 2″ screwed outlets to ANSI / ASME B1.20.1

- Ringlok Twin Ferrule Connections. Socket Weld and Butt Weld

- (All outlet connections are secured to prevent accidental dis-assembly)

Vent standard Vent connection is 1/2″ NPT (F) screwed connection. Others upon request.

Bore Sizes Ball Valves – 10 mm, 14 mm and 20 mm

Standard Features

Ball Valve Assemblies

Fully Floating Ball Valve Assemblies with cavity relief through the seats.

Needle Valve Assemblies

Both Heavy Duty Needle & OS&Y Valve Head Assemblies both incorporate a full range of features including:

- Colour coded dust cap protects the stem threads.

- Close tolerance glad pusher allows packing adjustment whilst in service.

- “T” Bar handle made from 304 or 316 stainless steel. Fastened to the spindle by a dowel type 304 or 316 stainless steel locking screw.

- Gland packing is PTFE as standard for temperatures up to 200ºC. Graphite seals are standard for temperatures up to 400ºC.

- Split stem designSpindle produced from 316 stainless steel.

ensures accurate seating and bubble tight seal. - Locking pinmade from 304 stainless steel ensures that the correct assembly torque of the valve head is maintained against the effects of vibration and/or temperature.

- Bonnet precision machined from 316 stainless steel, housing the gland packing below the actuating threads.

- Non-rotating trim made from 316 stainless steel, precision machined with spherical end to ensure a bubble tight seal.

Other Features

- Hydro static and or Gas Pressure Testing to BS 6755 Pt 1

- Fire safe to BS 6755 Pt 2

- Material thickness as defined in ANSI / ASME B16.34

- Flange Dimensions as defined in ANSI / ASME B16.5

- Standard Material Certification to EN 10204 3.1b

- Can be manufactured in a full range of standard and special materials to suit the application.