Piping systems are used in a vast array of applications, therefore pipe fittings and instrumentation used will need to provide for a series of fluid or gas control situations.

This includes high or low temperature extremes, the rise and fall of pressure, fluid flow and directional control and corrosion resistance.

Pipe Threads Explained

Throughout the fittings industry there are many types of connection threads used, the most common being, ‘pipe threads.’

There are two types of pipe thread, taper and parallel.

1. Taper Pipe Threads

These threads function by mating the male and female taper threads together, causing an ‘interference’ fit, where pressure-tight joints are made on the threads. A thread sealant is essential for this type of joint, that will also act as a lubricant to prevent galling during assembly.

2. Thread Sealant and Uses

Thread tape is appropriate for use on tapered threads (pipe fitting or component piece with screw-threaded ends for assembly.)

The correct sealant compatible with the application should be selected, the most widely used being PTFE tape.

PTFE tape, also known as plumber’s tape or thread seal tape, works as a deform-able filler and lubricant to help the sealing of joints. This sealing practice is used to make tightening easier, thanks to its lubrication of the connection. This method is commonly used in industrial applications for pressurised water and air compression systems.

There are two standard types of PTFE tape within the US. The first is a military specification that requires a minimum thickness of 3.5 mils (thousandth of an inch). The second is the commercial grade, A-A-58092 which maintains the thickness requirement of the first specification while adding a minimum density factor.

It is often used to correspond to colour coded pipelines within Canada, Australia and New Zealand. Within the UK, tape is used from coloured reels that correspond for certain applications.

EG. White tape is used on NPT threads up to 3/8”, while green ‘oil-free tape’ can be used on oxygen lines and other specific medical-related gasses.

Excess usage can cause the prevention of thread mating, disabling the ability for full joining of couplings.

It is recommended that 3-5 rounds of tape are applied in the direction of the thread to ensure adequate coverage and leak tightness of the joint is achieved. Other types of sealant should be used in accordance with the manufacturers recommendations.

3. Typical taper threads

NPT Taper Pipe Threads (ANSI/ASME B1.20.1)

ISO-BST Taper Pipe Threads (ISO 7/1 and BS21.)

ISO taper pipe threads are similar in appearance to NPT threads, therefore care should be taken not to mix these threads.

4. Parallel Pipe Threads

These threads are not designed to seal on the thread, they are designed to seal on adjacent faces by the use of a gasket.

Male threads are machines with a tapered undercut to centralise the gasket during assembly.

Parallel female threads are machined with a flat bottom face to accommodate an internal seal.

5. Piping Threads

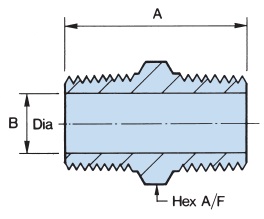

We manufacture stainless steel fittings with thread types NPT, BSPP, BSPT and NPTF(fuel), male and female end connections in imperial or metric sizing.

Recommended working pressures – pressure rating PSI

| NPT Pipe Size | Male | Female |

|---|---|---|

| 1/16 | 10,600 | 6,300 |

| 1/8 | 9,600 | 6,100 |

| 1/4 | 7,600 | 6,200 |

| 3/8 | 6,000 | 5,000 |

| 1/2 | 6,200 | 5,700 |

| 3/4 | 5,000 | 4,400 |

| 1 | 5,000 | 4,900 |

The pressure ratings shown above are in accordance with piping code ASME B31.1 and refinery code ASME for threads manufactured from 316 stainless steel.

All male threads are supplied with colour coded protective plastic caps to prevent handling damage, NPT threads have blue caps, whereas BSPT and BSPP threads will be red capped.

Other common piping thread standards:

• ISO 7/1 Tapered Pipe Threads

• ISO 228/1 Parallel Pipe Threads

• BSP British standard pipe thread – British standard thread

Common piping thread standards in the USA:

· NPT – American Standard Pipe Taper Thread (also known as ANSI/ASME B1.20.1)

· NPSC – American Standard Straight Coupling Pipe Thread

· NPTR – American Standard Taper Railing Pipe Thread

· NPSM – American Standard Straight Mechanical Pipe Thread

· NPSL – American Standard Straight Locknut Pipe Thread

Helpful links: