Compression fittings manufacturers Waverley Brownall have specialised in the design, manufacture and export of tube fittings and valves for many years.

From humble beginnings in a factory in London 1929, Waverley Brownall have since evolved into an instrumentation specialist company who supply products globally.

Areas of specialisation include manufacturing, pre-production design, bespoke solutions, engineering expertise, the machining of special metals to use in valves, tube and pipe fittings.

The sole manufacturing facility is located in Essex, United Kingdom. All design and machined parts are developed under strong brand values of high quality and standards of service. Waverley Brownall are approved by LLOYDS (BS part 4) and have maintained BS EN ISO 9001 since 1986.

This company is the approved supplier of Conoco Phillips, British Petroleum, British Gas, Shell and more. With next day delivery options available from Interlink Express, our fittings and valves can reach customers quickly – fully branded, marked with identification and packed securely for safe transportation.

Compression Fitting Manufacturers With Essex Headquarters

The beginnings of Waverley Brownall started in the UK’s capital city of London. Headquarters are now just outside the city in the county of Essex. The manufacturing hub is where one of our main bulk of stock is held, alongside our hardworking team.

Our departments include:

- Sales and Customer Services

- Stock holding

- Packing and delivery

- Inspection

- Testing

- Manufacture

- Marketing/Branding

- Administration

Tube Fittings And Pipe Fittings

Duoloc Single Ferrule Tube Fittings *BEST SELLER

Single ferrule compression fittings for tube application. Designed to be durable and robust, yet quick and easy to assemble. Extensively used within the Oil and Gas industry and hydraulic facilities.

Available in 316 stainless steel or any of our special metals including INCONEL, MONEL and INCOLOY.

Features: Compression nuts, blanking plugs, male/female, male/male, female/female fittings for tube ends. Tees, elbows, adaptors, couplings and many more.

Close tolerance manufacture ensures full interchangability of Waverley Brownall Duoloc fittings.

Assembly instructions are available on request. Training services by Waverley Brownall can be arranged for project specific requirements – the latest training session to take place was with engineers from National Grid who gained Waverley Brownall certification for an on-going gas metering project.

Ringlok Twin Ferrule Tube Fittings

Our tube fittings within the Ringlok range are single ferrule fittings developed for industries such as Oil, Gas, Pharmaceutical and others. Much like our Duoloc range, Waverley Brownall offer a range of sizes in metric and imperial measurements for these fittings.

Exotic materials for tube fittings such as elbows, stud couplings, bulkheads and more. These can be used with exotic material valves of the Waverley Brownall brand.

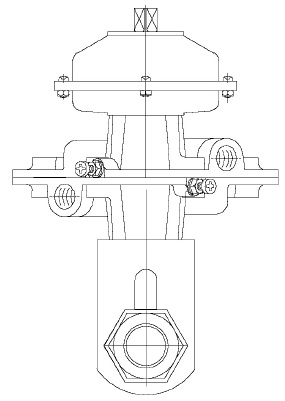

Valves (Ball, Relief, Needle and Check Valves)

Precision valves produced in Stainless Steel, Monel alloy 400, Incoloy, Inconel, Titanium and more.

A wide range of threads, sizes and pressure ratings are included with our valve range.

We offer many types of valve that are used in vapour, water or gas control and flow.

Acidic, marine and other highly corrosive materials can also be used within our valves with the correct material selection such as titanium. We suggest special metals manufacturing is a long-term solution for extreme environments.

1000, 3000, 6000PSI for Ball Valves. Varied range of PSI for valves.

Our extended range of Needle Valves can include a pressure rating of 10,000PSI.

FREE GUIDE To Selecting Metals

For Fittings And Valves

This FREE guide includes charts to help you select the right alloy for your fittings and valves depending on the intended application.

*This A5 Guide will be sent

directly to your address.