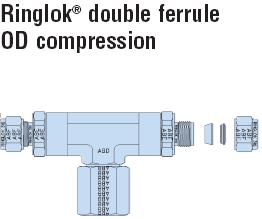

Our high quality Ringlok range of compression fittings are hugely popular with some of the biggest names in Oil & Gas – and with good reason.

Our twin ferrule compression fittings are available in high quality 316 stainless steel.

Alternatively, our fittings are available in a range of high performance alloys such as Hastelloy 276 for applications in highly corrosive environments.

Our reputation of quality and precision has been at the forefront of the Oil & Gas industry. Our fantastic standards of manufacturing, supply and innovative design has continued to delight our customers for many years.

Our Ringlok twin ferrule compression fittings are manufactured in the UK, but supplied to many industries across the globe.

- FEATURES

- BENEFITS

- IDENTIFICATION

- Low torque assembly and stress joint

- High surface finish to all threads

- Silver plating on the internal surfaces of the compression nut

- Cast code traceability

- Delivered assembled and ready for use

- Fittings available in 316 stainless steel or special metals such as Incoloy 825 or Titanium

- Corrosion resistant hard casing to back ring

- Easy make-up of joint

- No stress transmitted to the tube

- Positive alignment to tube fitting

- Full interchangeability of all Ringlok components

- Suitable for corrosive environments

- Prevention of thread damage

- Instant recognition of connecting end type

Only forgings in the metric range are marked ‘mm’.

Ringlok products are cast code marked to enable material traceability.

All fitting bodies and nuts are marked with material type and product name.

Identification collar on nut and body of bar stock fittings signifies the Ringlok metric range.

For more information contact us today by Email. We will respond to any questions you may have about our Ringlok range.

enquiries@waverleybrownall.co.uk